Miura-ori

Made up of interlocking parallelograms, this pattern has some very useful properties that make it practical for use in deployable structures.

Firstly, every panel moves simultaneously with each other, relying only on some fold angle θ. This means that this pattern only has one control parameter, and the entire system moves simultaneously based on this. Miura-ori simplifies deployment kinematics by constraining motion to a single degree of freedom, which can save time in disaster situations.

This pattern also allows structural depth to be created from a flat shape. As the fold angle increases, the geometry naturally develops corrugation, adding depth perpendicular to the original plane. This depth is directly related to the fold angle, with the height increasing in proportion to sin (θ).

Another feature of Miura-ori is that it can provide necessary stiffness in design, with its corrugated nature resisting torsion and local deformation.

Miura-ori crease patterns can fold very small compared to their expanded size, making them ideal for portability and deployability.

Prototypes

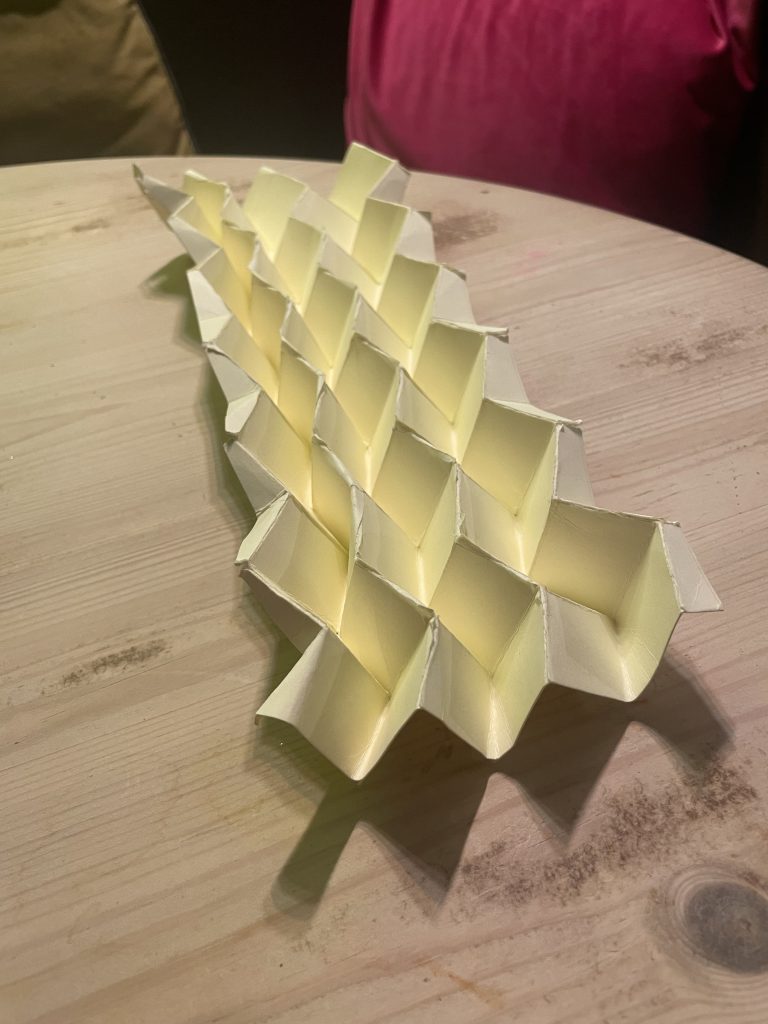

I decided to model the Miura-ori in real life by constructing my own models to explore it’s motion practically. I choose first to use a laser cutter to score folds in some thick card, and marking each fold separately before bringing the pattern to life.

I found that, although this approach was effective, the card was prone to ripping and the final product did not behave full like Miura-ori should. I could test it’s load-bearing strength quite easily, and I found that it could hold much heavier objects that the thick card alone would have done.

I explored how compact the pattern could fold, with the fully expanded length being approximately eight times longer than the flat-folded version. This makes this crease pattern very useful for portability and quick assembly in dangerous environments.

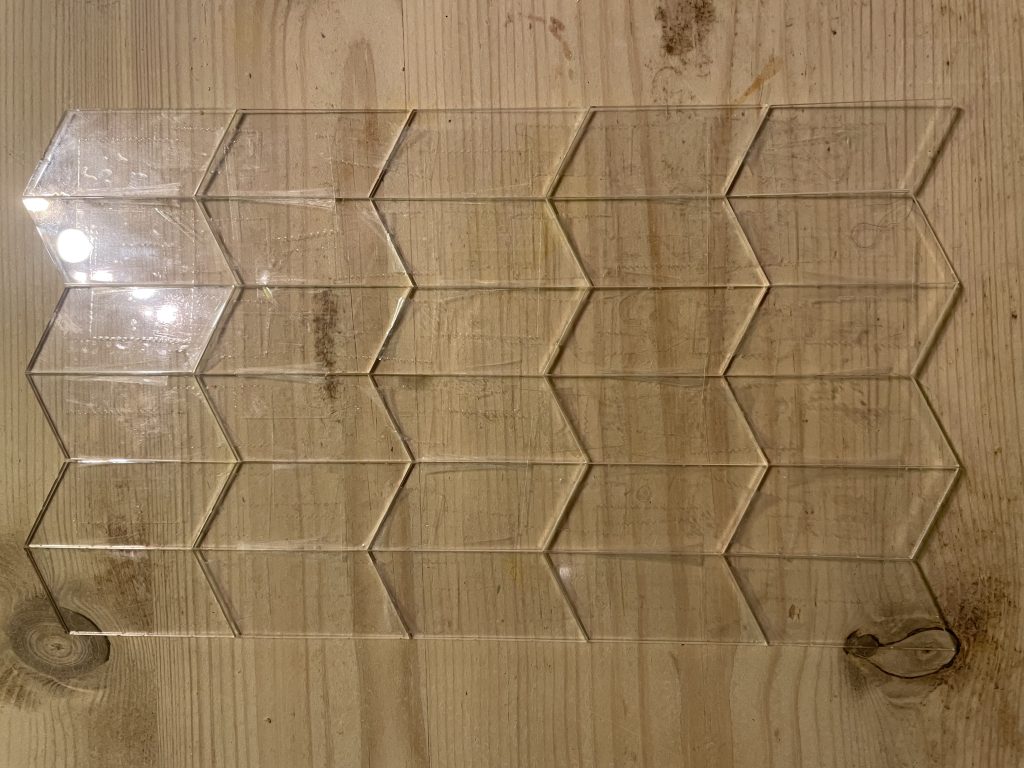

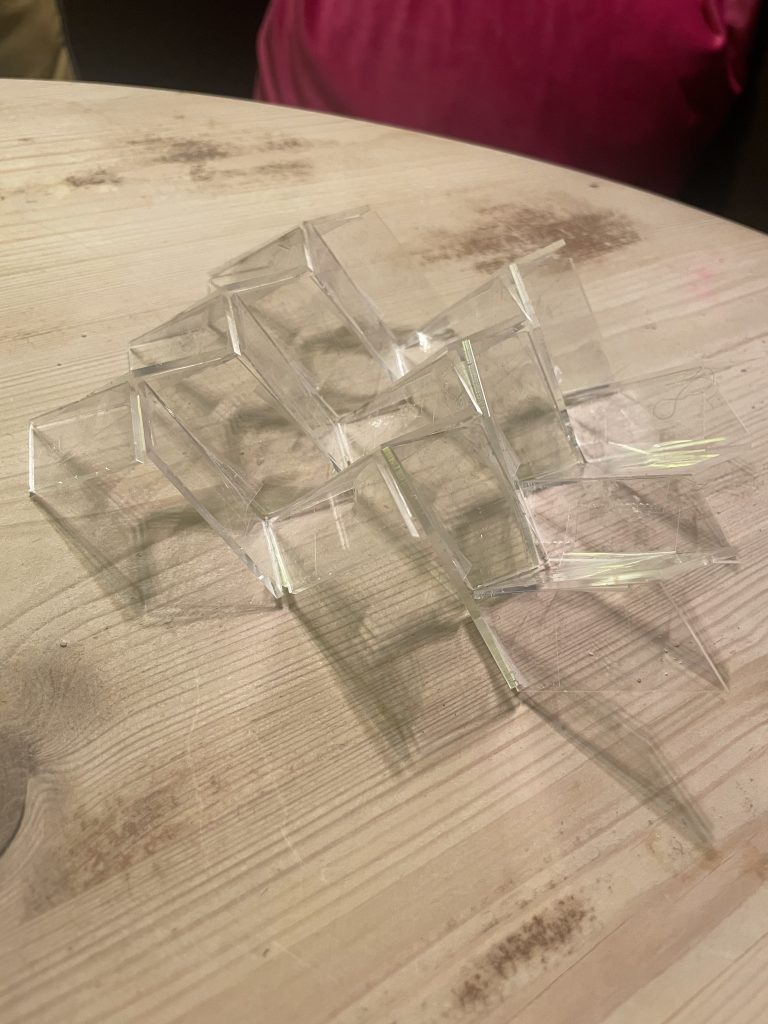

I then began exploring how I could make it out of more rigid panels to better reflect the materials that would be used in deployable structures. I realised that scoring a thicker sheet of plastic would give little room to fold and would be very hard to work with. Instead, I used individual clear acrylic panels and tape to create a fully functional Miura-ori model.

This is the model after laser-cutting and taping. Each piece of tape served to connect the valley fold of each crease.

I constructed the 3D model in one go, manoeuvring the material. This provided a much more accurate representation. However, the folds were still not fully accurate; I was unable to tape the entire fold each time, so the panels were not fully in tandem with each other.

I decided to go back to the idea of a single sheet being folded into the finished structure. I just had to find the right one for this application.